Welcome

Nationwide Electrical & Mechanical Services for Heavy Industry

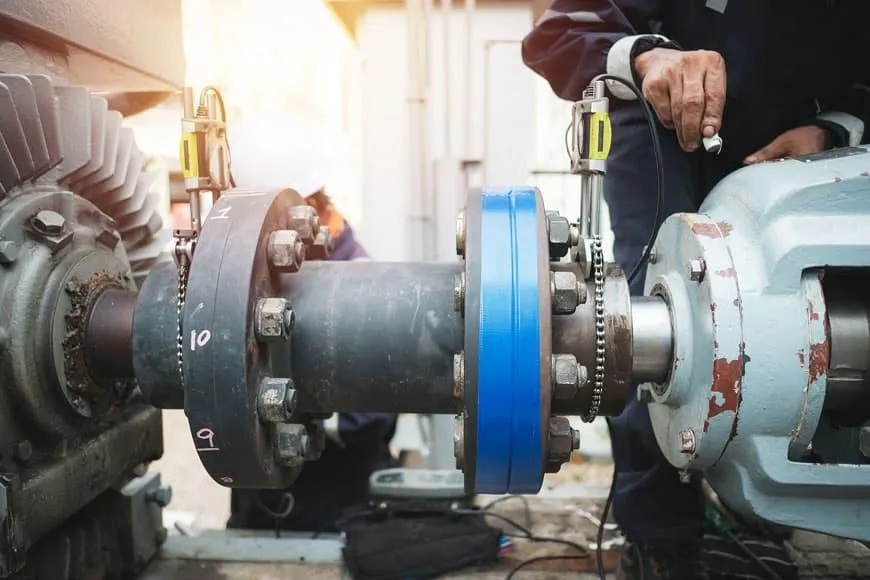

Alpha Industrial LLC specializes in heavy industrial electrical and mechanical installations and maintenance. We are a veteran-owned and operated company with over 50 years of combined experience, dedicated to providing exceptional service and reliable solutions.

ABOUT US

Alpha Industrial LLC provides expert electrical and mechanical services for heavy industry. Our founders bring over 50 years of combined experience, enabling us to deliver reliable solutions for complex industrial needs. . Our team offers diverse skills, including NCCER Rigging and Crane Operations, Journeyman Millwright, Journeyman Substation Technician, and welding and machining expertise. As a veteran-owned company, we are committed to exceptional service and strong client partnerships.

OUR SERVICES

Electrical Solutions

We provide comprehensive electrical solutions for heavy industry, including high-voltage installations, industrial wiring, and automation systems, ensuring reliable power and efficient operations. Learn more about our electrical installations, repairs, and maintenance.

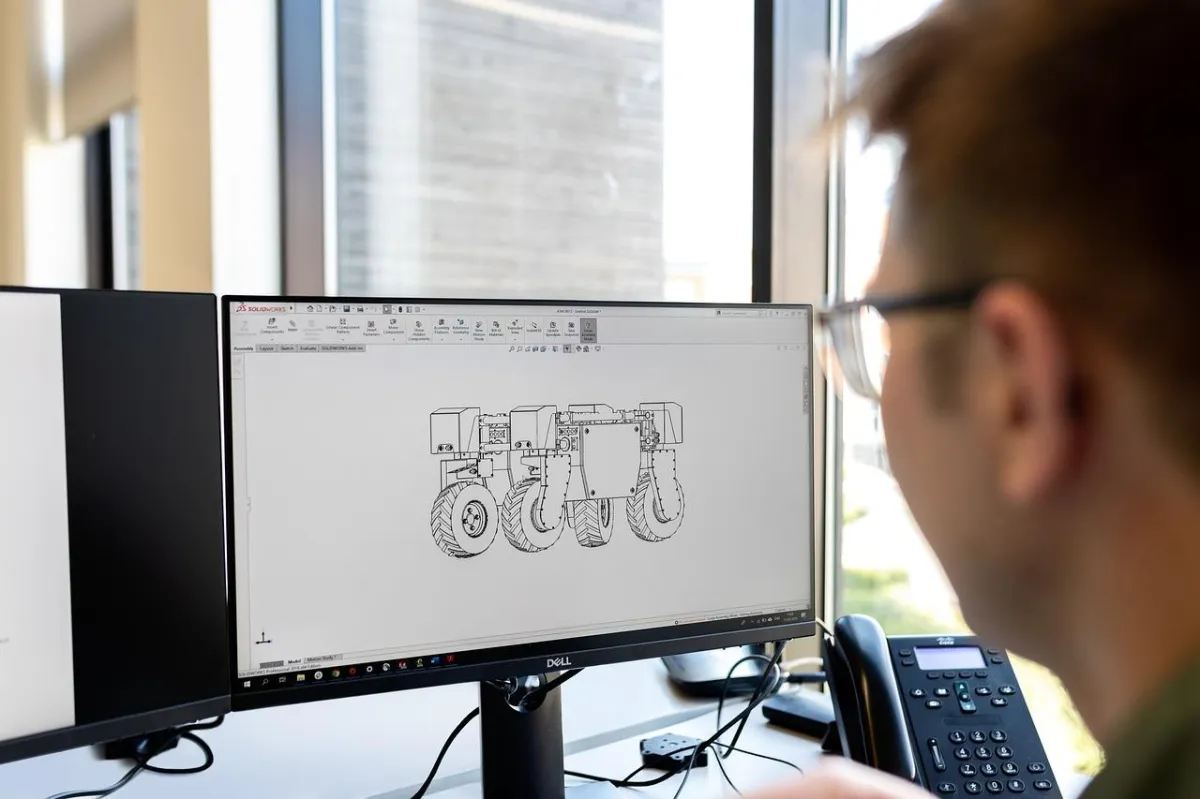

Mechanical Automations

We design, install, and maintain automation systems for manufacturing facilities, increasing productivity and optimizing production processes. Explore our automation solutions to streamline your operations

Mechanical Operations

Alpha Industrial LLC offers a full suite of mechanical services, from the installation and upgrades of heavy machinery to ongoing maintenance and repairs, keeping your production lines running smoothly. Discover our expertise in mechanical systems and insulation.

Ongoing Maintenance Contracts

Maximize uptime and minimize disruptions with our customized maintenance plans, designed to prevent costly breakdowns and extend the life of your equipment. Check out how our proactive maintenance approach can benefit your facility.

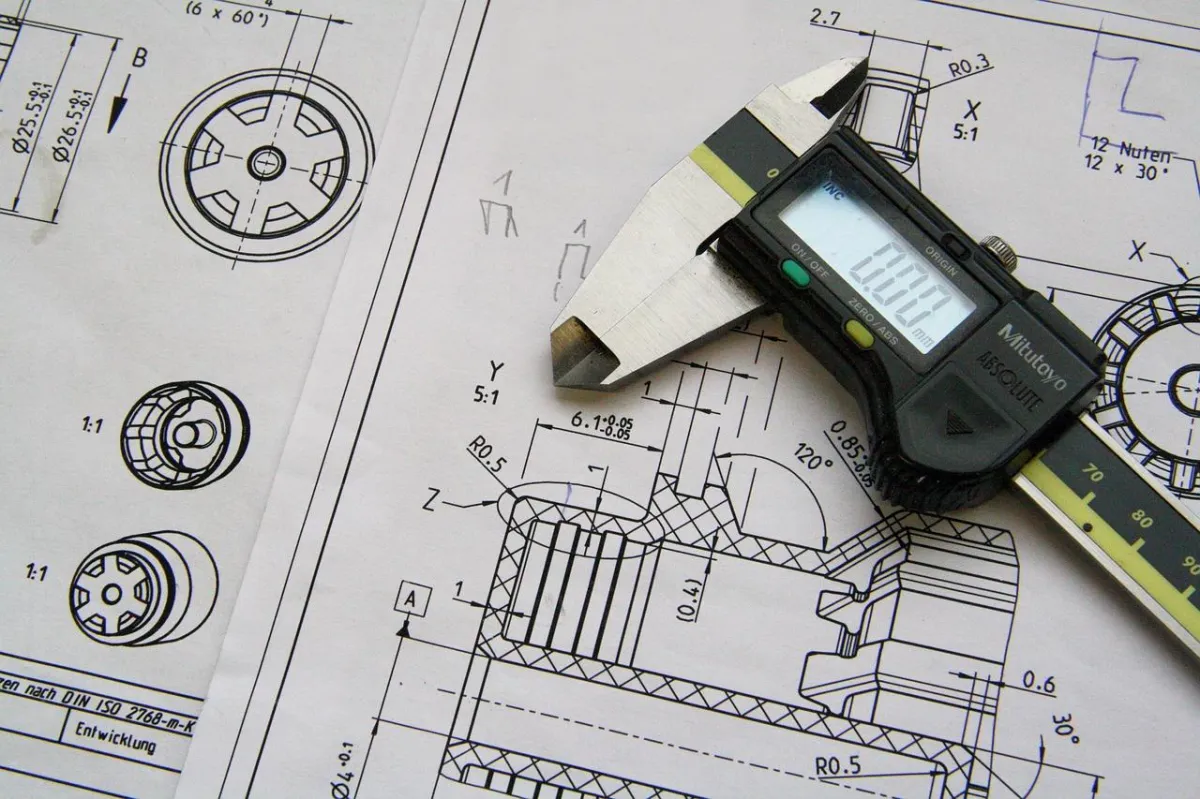

Certifications and Specialized Skills

Our team offers diverse skills, including NCCER Rigging and Crane Operations, Journeyman Millwright, Journeyman Substation Technician, and welding and machining expertise. As a veteran-owned company, we are committed to exceptional service and strong client partnerships

NCCER Rigging and Crane Operations

This certification demonstrates expertise in safely and efficiently using rigging equipment and cranes to lift and move heavy loads, crucial for industrial installations and maintenance.

Journeyman Millwright

A Journeyman Millwright possesses the skills to install, maintain, and repair industrial machinery and equipment, ensuring the smooth operation of manufacturing and production facilities.

OSHA Compliance

Adherence to OSHA standards demonstrates a commitment to ensuring that all operations are conducted in accordance with regulations to protect workers and prevent accidents.

MIG, TIG, and Stick Welding

These are various welding processes, indicating proficiency in joining metal components using different techniques, a vital skill for fabrication and repair work in industrial environments.

Journeyman

Substation

Technician

This certification indicates specialized knowledge in the installation, maintenance, and repair of electrical substations, which are essential for power distribution in industrial settings.

FAQS

How do ongoing maintenance contracts help minimize downtime and improve production efficiency?

Our customized maintenance contracts are designed to proactively identify and address potential issues before they lead to breakdowns. By scheduling regular inspections, lubrication, and parts replacements, we help you avoid costly unplanned downtime, maintain optimal equipment performance, and maximize your production output. We also provide detailed reports and data analysis to help you track equipment health and make informed decisions.

What is your approach to troubleshooting and resolving complex mechanical issues with our machinery?

Our experienced millwrights and technicians use a systematic approach to troubleshooting. This includes: Thoroughly inspecting the equipment and gathering information about the symptoms. Using diagnostic tools and techniques to pinpoint the root cause of the problem. Developing a clear repair plan and communicating it to you. Performing the repair efficiently and effectively, using high-quality parts and proven techniques. Testing the equipment to ensure it's functioning properly before returning it to service.

Can you provide detailed proposals and cost estimates, and how do you ensure projects stay within budget?

We provide detailed proposals and cost estimates that clearly outline the scope of work, materials, labor, and any other associated costs. We manage projects to stay within budget by: Developing a realistic project plan and timeline. Closely monitoring expenses throughout the project. Communicating any potential cost changes to you promptly. Seeking your approval for any changes to the scope of work.

INDUSTRIES AND BUSINESSES WE SERVE

Manufacturing Plants

Automotive Manufacturers

research and Development facilities

oil and gas companies

industrial facilities

companies REQUIRING emergency repairs

companies planning facility UPGRADES or expansions

utility plants

Warehouse and DISTRIBUTION centers